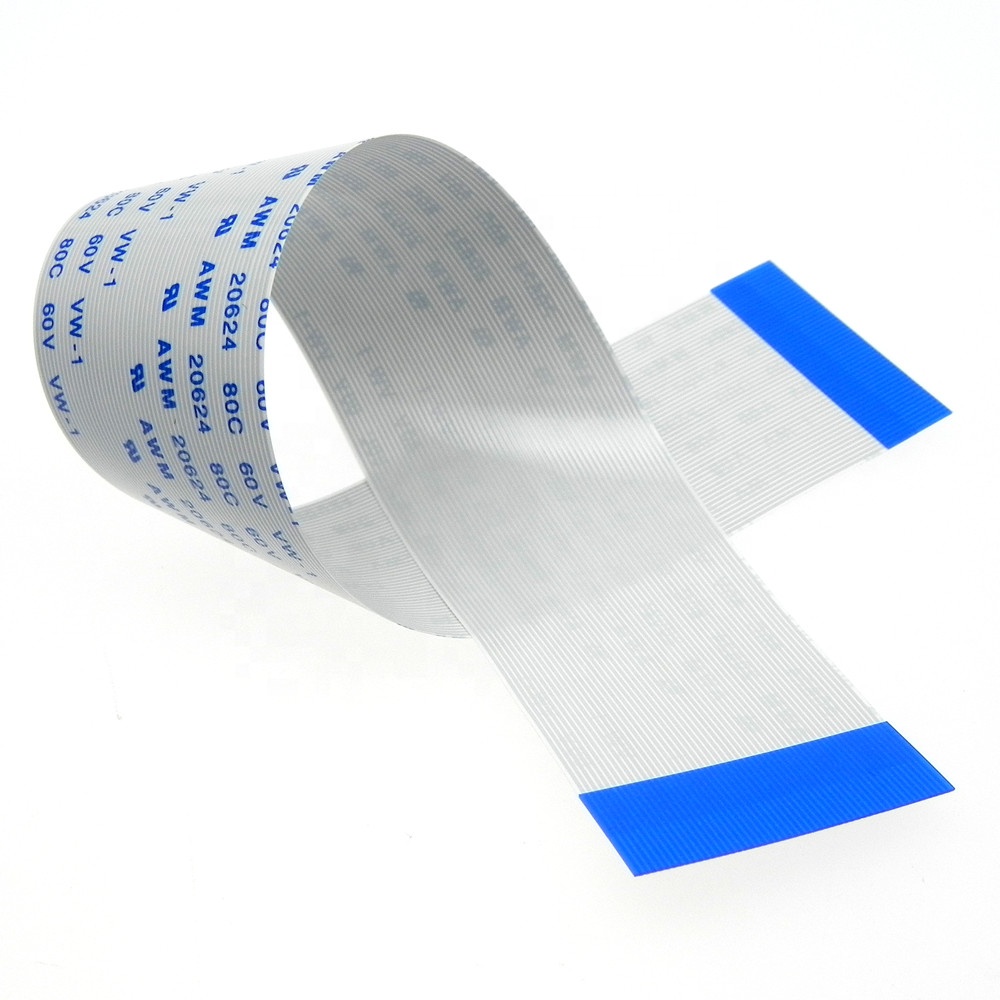

In a world where electronic devices are becoming increasingly compact and powerful, Flexible Flat Cables (FFC) play a critical role as hidden enablers. These flat, flexible conductive pathways have revolutionized connection technology for decades – from smartphones to industrial robots.

What is an FFC Cable?

FFC stands for Flexible Flat Cable, referring to ultra-thin interconnect solutions composed of parallel copper conductors protected by a flexible insulating layer (typically polyester or polyimide). Unlike traditional round cables, their flat design enables space-saving installations in cramped enclosures.

Structure and Variants

A typical FFC cable consists of:

- Copper conductors (0.035–0.1 mm thickness) with tin or gold plating

- Insulation materials like PET (heat-resistant up to 105°C) or PI (up to 200°C)

- Connectors with pitch sizes ranging from 0.3 mm to 2.54 mm

Modern variants even integrate shielded versions (FFC/S) for high-frequency applications or twisted pairs to reduce interference.

Application Overview

| Industry | Use Cases |

|---|---|

| Consumer Electronics | Smartphone displays, laptop cameras |

| Automotive | Airbag controls, infotainment systems |

| Medical Technology | Endoscopes, wearable sensors |

| Industry 4.0 | Robotic arms, CNC controllers |

Advantages Over Conventional Cables

- Space Savings: Up to 80% thinner than round cables

- Flexibility: Up to 10 million bending cycles (per IEC 60668-2)

- Signal Integrity: Low crosstalk due to fixed conductor spacing

- Cost Efficiency: Enables automated mass production

Challenges and Solutions

Despite their advantages, FFCs require special handling:

- Shear Force Sensitivity: Special guide rails during installation

- Limited Current Capacity: Max. 0.5 A per conductor (solution: parallel circuits)

- EMC Issues: Shielded or twisted-pair variants

Future Prospects

With the development of 5G technologies and flexible electronics (e.g., foldable displays), demand for high-frequency FFCs up to 40 GHz is rising. Simultaneously, eco-friendly materials like biodegradable polymers are driving sustainability efforts.

Conclusion:

FFC cables embody the perfect synergy of miniaturization and high-performance engineering. As key components in our connected world, they will continue to push the boundaries of technical feasibility – invisible yet indispensable.